The outcome every project owner ultimately seeks is accuracy in construction, based on the approved design. Accurate site setting out is fundamental to achieving this.

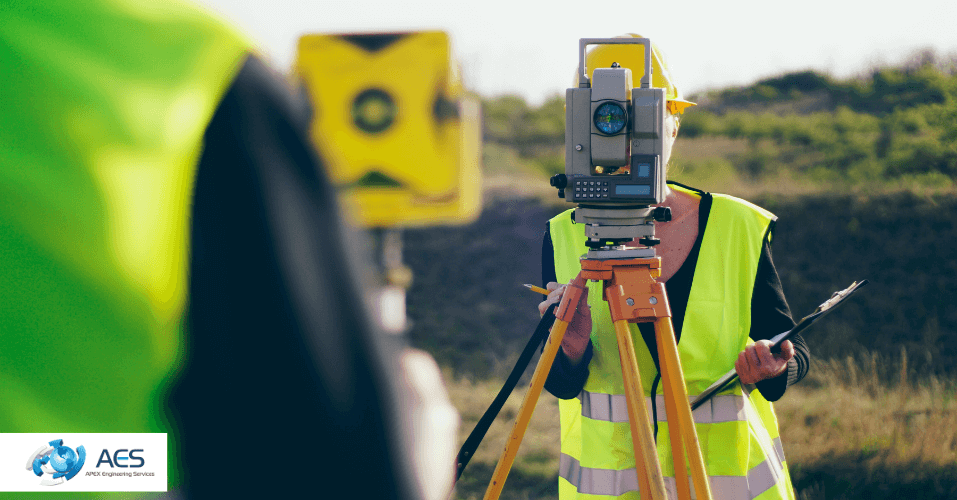

At Apex Engineering Services, our setting out surveys significantly reduce human error and assumptions through the use of GPS technology, robotic total stations, and 3D laser scanning. These advanced surveying technologies ensure that structures, levels, and boundaries are positioned exactly where they should be from the very start.

By working with precise data and proven methodologies, the risk of mistakes is minimised, efficiency is improved, and overall project accuracy is maximised.

In this blog, we explain how accurate site setting out plays a key role in reducing the likelihood of construction delays.

Equipment Used in Site Setting Out — and How It Improves Accuracy

GPS (Global Positioning System)

Apex Engineering Services’ surveyors use GPS technology to establish accurate control points and location data across a site. GPS receivers calculate precise coordinates by comparing signals received from satellites, allowing engineers to determine exact positions on the ground.

These verified reference points form the foundation for all subsequent setting out works. When control is established accurately from the outset, the likelihood of rework — a major cause of construction delays — is greatly reduced.

Robotic Total Stations

Robotic total stations are used to measure distances, horizontal angles, and vertical angles with exceptional precision. Apex Engineering Services utilises Leica robotic total stations, which automatically track a prism (target) without the need for a second operator.

These instruments use high-frequency Electronic Distance Measurement (EDM) technology to provide fast and reliable measurements. This allows surveyors to transfer design coordinates directly from CAD models onto the site with millimetre-level accuracy.

Did You Know?

GPS and robotic total stations work together. GPS establishes accurate site control, while the total station uses those control points to set out detailed building elements. If control is inaccurate, everything built from it will also be inaccurate — leading to costly corrections and potential delays.

3D Laser Scanning

One of the most common causes of project issues is a lack of reliable information about existing site conditions.

Apex Engineering Services uses 3D laser scanners to capture millions of measurements and generate highly detailed digital models of sites. These models allow designers and contractors to clearly see:

- Existing structures

- Surface conditions

- Visible utilities and obstructions

By comparing scan data with design information, potential clashes and inconsistencies can be identified early. This significantly reduces the need for rework and helps prevent unforeseen problems during construction.

Why Site Setting Out Should Be a First Step in Pre-Construction

Accurate site setting out ensures that:

- Building footprints, gridlines, and levels are positioned exactly to design

- Foundations are constructed in the correct location and at the correct elevation

- Drainage runs and utility routes are properly coordinated

- Manual calculations are largely eliminated

Together, these benefits lead to smoother workflows, fewer errors, and a greatly reduced risk of delays.

Frequently Asked Questions

How does accurate site setting out help prevent construction delays?

Accurate site setting out ensures that all structures, boundaries, and levels are positioned exactly according to the approved design. When measurements are correct from the start, errors such as misaligned foundations or incorrect levels are avoided — preventing costly rework and programme delays.

What types of mistakes cause delays when site setting out is inaccurate?

Common issues include incorrectly positioned foundations, wrong building lines, clashes with underground services, and level discrepancies. These often require demolition or corrective works, which significantly impact time and cost.

How do modern surveying technologies reduce project delays in the UK?

Technologies such as GPS, robotic total stations, and 3D laser scanning deliver highly accurate site data. They eliminate manual errors, improve coordination between design and construction teams, and allow potential issues to be identified early.

Can accurate site setting out help avoid clashes with underground services?

Yes. When combined with survey data and 3D laser scanning, accurate setting out helps identify existing utilities and drainage routes before construction begins. This prevents unexpected discoveries that can halt progress.

Why should site setting out be completed before construction begins?

Site setting out translates design information onto the ground. Without it, construction relies on assumptions rather than verified positions. Proper setting out ensures smoother workflows, better coordination, and on-time project delivery.

Conclusion

Accurate site setting out is essential for delivering projects on time and to specification.

By using advanced technologies such as GPS, robotic total stations, and 3D laser scanning, Apex Engineering Services removes uncertainty at the earliest stage of construction. Errors are reduced, risks are identified sooner, and construction teams can work with confidence.

For reliable setting out surveys, improved efficiency, and reduced delays, contact Apex Engineering Services.