A few years back, it was highly difficult to predict how your project would turn out after completion. There was one particular question lingering in your mind, whether it will be according to your requirements? Not known.

But now in this advanced time, where technology is not only entering fashion and IT fields, but also the construction field as well. It means now you can see the accurate 3D model of your project with the help of 3D laser scanning.

For that reason, Apex Engineering Services' laser scanning is essential for enhancing security and lowering risk in infrastructure projects in the UK. The detailed models that are generated through 3D laser scanning enhance planning, lessen human error, and facilitate the early detection of any problems before building starts.

As a leader in 3D laser scanning infrastructure UK-wide, Apex Engineering Services ensures every detail is captured accurately to support safer, smarter construction decisions. Through the blog, let's get to know it more.

What is 3D-Laser Scanning?

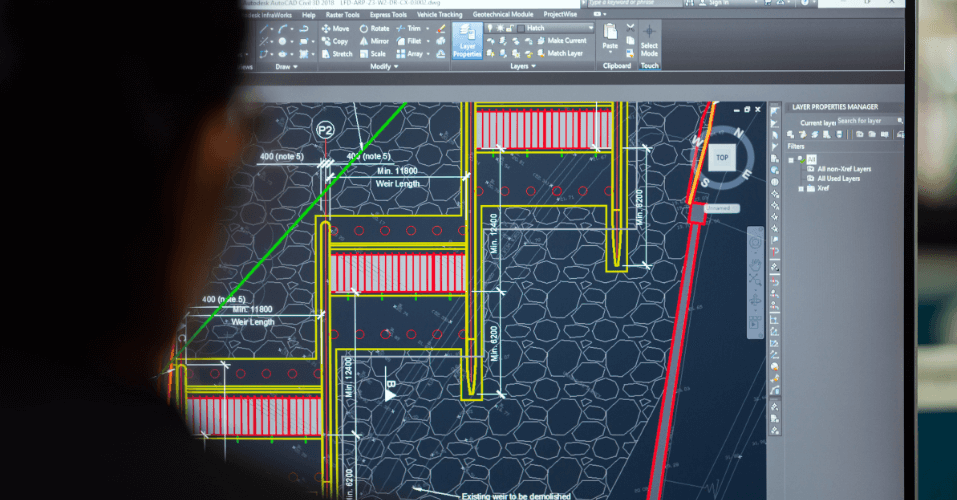

Laser scanning is not only about collecting data. The major aim of using this advanced tool is to accurately depict the dangerous settings like tunnels, bridges, and railroads. The experts of Apex Engineering Services use 3D laser scanning to scan subterranean utility tunnels and rail platforms.

After that, the scans are transformed into complicated 3D point clouds that enable engineers to precisely comprehend each measurement and structure.

This lessens the necessity for frequent site visits, particularly in inconvenient places like active railroads. Employees are not required to spend a lot of time physically present in dangerous areas.

Rather, the laser only records the scene once, and the information can be utilised from the security of a planning centre or office.

Reducing Risk During Rail and Tunnel Work

In the UK, working in cramped or complicated spaces is a common part of infrastructure projects. Do not worry about anything because Apex Engineering Services demonstrates how 3D laser scanning directly lowers project risk in utility tunnels and rail engineering.

According to the case study, their engineers finished a comprehensive survey of a sizable system of underground utility tunnels in 10 days, five days ahead of schedule, during one project. In record time, they collected all the required data using a Leica HDS scanner.

This quick and effective method cuts down on delays and the likelihood of an on-site mishap. They give constructors the knowledge they need to prevent accidents by outlining every element, including cable routes and clearance levels.

In fact, laser scanning risk reduction has become essential in enhancing safety by ensuring every detail is accurately mapped. Hence, there is no guesswork because every aspect is documented.

5 Major Benefits of Selecting 3D-Laser Scanning

1) Preventing Errors Before They Happen

After using AES 3D laser scanning, you have an accuracy of results. Without relying on speculation, this kind of accuracy facilitates problem identification, retrofit planning, and infrastructure development. This is essential for railway projects because exact measurements are required to prevent system failures.

Finding any faults between design and reality is made easier by the as-built models that are produced from the scans. However, teams of Apex Engineering Services can identify possible problems before any work ever starts, such as whether a new cable route crosses over into an existing pipeline.

The likelihood of expensive mistakes is greatly reduced when designs are grounded in real-world data.

2) Remote Access and Monitoring with TruView

One of the noteworthy technologies Apex Engineering Services delivers with its laser scanning is Leica TruView. Users can remotely observe and interact with scanned environments thanks to this programme.

It is more than just viewing images. Builders can collect measurements straight from the scan, zoom in on important locations, and virtually walk through a tunnel.

This eliminates the need for decision-makers to go into risky locations. Sites can be inspected from any location. With the rise of 3D laser scanning infrastructure, UK projects are now benefiting from precise and remote data collection.

The same data is available to all stakeholders, enabling prompt and well-informed decision-making. This improves safety and saves time for infrastructure projects located around the United Kingdom.

3) Compliance with National Standards Ensures Reliability

In addition to being high-tech, AES laser scanning services follow strict UK requirements. For example, they adhere to Network Rail specifications such as NR/L2/IDI/EDT/CP0091 and NR/L2/TRK/3100 when conducting rail surveys. This guarantees that the information gathered satisfies the requirements of transportation authorities and regulators.

This type of dependability instils confidence in engineers. It lessens planning and construction uncertainty, which in turn lessens the likelihood of an unanticipated delay or safety concern.

4) Faster Turnarounds Mean Quicker Risk Response

Timelines for infrastructure projects are very strict. Traffic jams, safety concerns, and increased expenses are the common causes of delays. Decisions can be made more quickly because of AES's speedy scanning and data distribution procedure.

Just like in the utility tunnel project, they finished scanning in ten days and turned in all of the deliverables, including cross-sections and detailed drawings, in a month.

This highlights that engineers can proceed with confidence rather than having to wait weeks for measurements or revisions. Hence, as laser scanning risk reduction UK practices become more common, construction can proceed without needless disruptions when issues are resolved.

5) Improving Safety Through Clear Communication

With the help of 3D laser scanning, everyone can view the same conditions and get the same scan findings, including project managers and engineers. Misunderstandings are not tolerated.

Collaboration is improved because of this open communication. To discuss the scans, identify concerns, and develop solutions, teams can meet virtually. Everyone has a comprehensive understanding of the site conditions, which increases efficiency and safety. This approach clearly shows how 3D scanning enhances construction safety in the UK projects by enabling real-time insights and more accurate decision-making.

What are the questions that people have for Apex Engineering Services?

How does 3D laser scanning help improve safety on construction sites?

3D laser scanning reduces the need for workers to physically access dangerous or hard-to-reach areas. Instead, the site is scanned once, and the detailed data can be reviewed remotely. This limits on-site exposure and minimise the risk of accidents during inspections or measurements.

Can laser scanning actually prevent construction errors?

Yes, laser scanning creates accurate digital models that reflect real-world conditions. These models help engineers spot design clashes or errors before construction begins, preventing costly and risky mistakes on-site.

How accurate is the data collected by laser scanning?

Laser scanning used by companies like Apex Engineering Services offers accuracy. This high level of precision ensures that plans and decisions are based on reliable information, reducing uncertainty and improving safety.

Does laser scanning reduce delays in infrastructure projects?

Yes, by quickly capturing site data and providing fast digital deliverables, laser scanning speeds up the planning process. Fewer errors and less rework also mean projects stay on schedule, reducing risks linked to delays and unexpected changes.

How is laser scanning data shared with project teams?

The scanned data is often shared through tools like Leica TruView, which allow remote viewing and virtual walkthroughs of the site. This enables better collaboration, faster decisions, and clearer communication between teams, all of which contribute to a safer project environment.

Conclusion

Apex Engineering Services’ work in 3D laser scanning infrastructure UK projects helps lower risk at every stage of a project by providing remote-access solutions like TruView, cutting down on time spent on-site, and properly documenting real-world conditions.

Safety is a top priority in utility networks, railroads, and tunnels. AES backs up that promise with laser scanning solutions that are quick, accurate, and compliant. So, directly contact their team for safer futures for all parties involved, smarter judgments, and fewer accidents.